Product Gallery

At Valor Company, our 54 years of experience, extensive array of equipment, and long-term professional staff have enabled us to tackle many different projects. Learn more about our capabilities by browsing some examples of past and present works.

Tube Bending

-

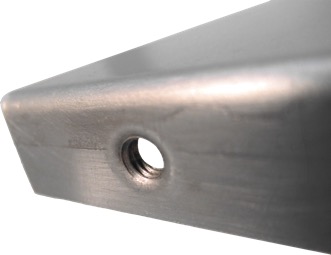

Flow drilled and tapped holes -

Joystick handle with part number -

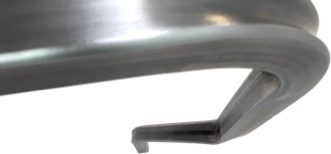

Solid bar handrail with a bead-blasted finish -

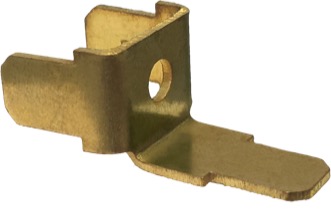

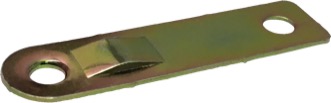

Flattened end with a 90° form -

Angle-cut end -

Pierced hole through one wall; a dimpled hole is achieved by not using a mandrel -

Flow drilling is used to extend wall diameter -

Rectangular tube with a key hole -

TIG welded -

A piece showcasing radius end cutting / complex end cutting -

2″ tube with a long roll bend, followed by a tight rotary bend -

End notching -

We work with tubes of all sizes -

Large crush-bent component from square tubing -

A large welded tube product, assembled in-house -

Roll bent 2″ diameter tube -

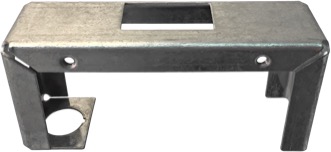

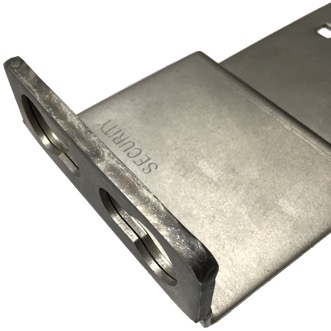

6′ long tractor Roll-Over Protection System (ROPS) bracket -

Stainless steel suction-pump wand; welded with a passivated finish -

1″ tube with flattened center and 3″ flattened end -

Flattened mid-section of a tube -

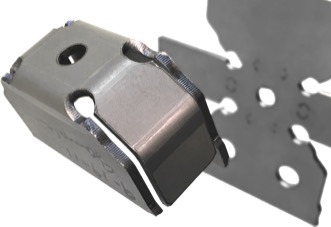

Two formed and flattened ends; component on left joined by weld -

Milled end coping -

1 1/4″ formed tube with pierced slots and hole -

2′6″ × 1′6″ × 1′6″ stand — bent from single 1″ tube -

Complex CNC bending -

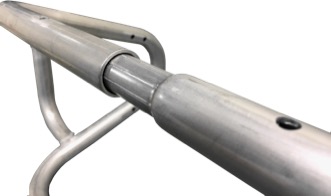

Handlebar for a post-hole digger -

A drilled and tapped tube -

Chamfered end with flattened middle -

End formed top -

1″ solid bar -

1 3/8″ solid bar; end flattened to 5/8″ with 7/8″ diameter drilled hole -

This large, heavy-gauge tube is part of fire engine’s rollover protection structure -

The stampings, tubing, and welding for this gate assembly are all completed in-house -

Flattened tube end with pierced, countersunk hole -

CNC bent tube with additional component attached via weld -

ATV door frame -

Part of an industrial paint sprayer, 29″ × 35″ -

Complex bending angles -

1″ square tube, 48″ × 16″ -

Crush bent to 90° -

Produced from single tube, bent to make ends meet -

Flattened tube end is pierced to create oblong hole, then again through one wall to create round, dimpled hole -

Weeding tool for a garden or yard -

Welded, finished assembly -

MIG welded small engine exhaust manifold -

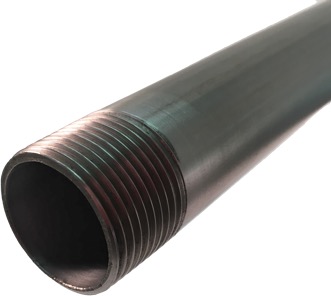

External pipe threading -

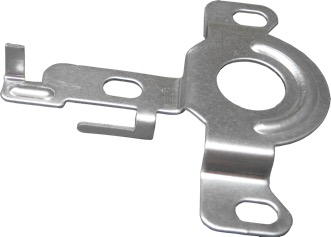

The internal structure of a steering joystick -

Pierced, dimpled hole through one wall -

Complex tube forming and piercing -

1/2″ tube with milled-through slot and pierced hole -

Portable medical device frame, coated with a textured urethane paint -

5/16″ wire/rod -

Tractor door pin -

Stainless steel medical tubing -

3/8″ × 3″ formed medical pump tube -

Medical-grade bath chair frame -

Bent solid bar -

2″ treadmill handrail -

Drain tube, stainless steel -

Aluminum pierced through both walls; mandrel used to prevent material dimpling/sinking around holes -

Train locomotive handrail -

Two-piece assembly -

65° mitered end -

Swedged assembly -

Welded tube assembly -

Bent from a single tube -

Tube with pierced holes -

TIG welded round tube -

Exhaust manifold -

Mandrel punched holes -

MIG welded -

Safety equipment stand